商用车

2022-02-08

优化移动液压系统可使难以电动化的拖拉机降低排放

Brianna Jackson

Brianna拥有生物学和化学学科背景,她对可持续发展和医疗技术有着浓厚的兴趣,为IA团队在这些领域的专业知识增添了更深层次的洞察和见解。

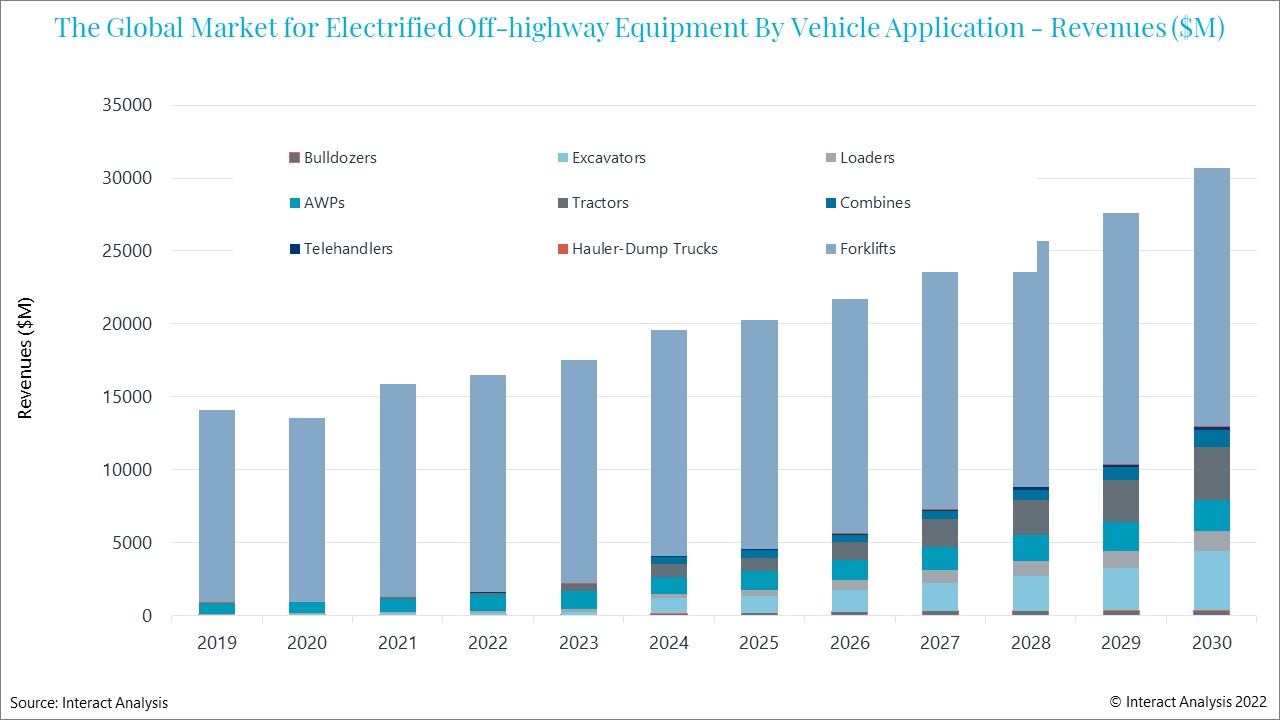

Hydraulic systems use a lot of energy. So, in anticipation of widespread electrification, vendors selling hydraulics into the off-highway vehicles market have focused a lot of effort on improving efficiency. We’ve written before about the challenges facing the electrification of construction machinery. But when it comes to agricultural machinery, these challenges are greater still. Full vehicle electrification will be particularly slow in agriculture for three main reasons: lack of pressure to meet environmental regulations, cost constraints, and the existence of cost-effective alternatives. This means that the pressures facing suppliers of hydraulic technology to the agricultural sector, are unique.

Tractors are slowly electrifying, but there are other ways to decarbonize agriculture

The agricultural sector is particularly cost-sensitive due to low margins. While vendors such as Solectrec, Sonalika, and Monarch Tractor have manufactured electric compact tractors, these tractors carry a higher price tag than comparable diesel tractors. For example, Solectrec’s tractors are 20% more expensive than similar diesel ones. The average crop farm in the U.S. spent $8,119 on tractors and self-propelled farm equipment in 2018, which underlines the degree to which the market for agricultural equipment in the U.S. heavily favors maintenance of equipment rather than replacing machines as farmers tend to hold off on replacing equipment as long as possible. The business model of agricultural machine manufacturers reflects this, and companies such as John Deere generate most of their revenues from after-sales service.

While diesel prices are a concern for farmers, the cost of fuel pales in comparison to the cost of charging infrastructure for EVs. According to the USDA, the average crop farm spent $8,920 on fuel in 2018. This contrasts an estimated price for a basic charger for farming equipment of $50,000 (according to the former CEO of a battery company who spoke at a US govt agriculture hearing in Jan 22). Additionally, a basic charger alone would likely not be enough for most farms as charging times would be too long: more powerful rapid chargers would also be required which would likely cost twice as much. All this makes fully electric tractors and combines a tough sell for the average American farmer.

Decarbonizing agriculture cannot, therefore, be about electrifying machinery for the foreseeable future. And that’s less of a problem than it sounds, because only 12% of agriculture’s greenhouse gas emissions are from CO2 anyway, with 88% coming from methane and nitrous oxide. Ultimately, therefore, agriculture can make massive strides towards carbon neutrality while still relying on diesel powered vehicles. But that doesn’t mean we can’t reduce emissions from agricultural machinery. To this end, improving the efficiency of hydraulic systems is key, even if the vehicle itself is still running on diesel. Agricultural equipment already tends to feature more economical hydraulic technology, such as gear pumps. However if switching over to axial pistons, or even to more sophisticated technologies such as digital displacement pumps, can boost efficiency by 10-15%, the savings in fuel costs might well be significant enough for farmers to upgrade their equipment.

Cutting carbon with hydraulics

Electrifying the implements attached to tractors may be instrumental in decreasing emissions in two ways. First, it can save energy through efficiency. Second, it can deliver more precise control which cuts emissions indirectly. For example, in a practice known as variable rate planting, the rate at which seeds are planted is adjusted in a field according to the properties and needs of the soil throughout the field. This reduces seed waste, increases crop yield, and (crucially, from an emissions perspective) reduces the quantity of fertilizer and fuel required.

In the case of variable rate planting, it is typically enabled by hydraulics, specifically by a hydraulic drive. Advanced hydraulic drives can easily provide enough control for farmers to engage in precision agriculture. Therefore, hydraulic upgrades to agricultural machinery can offer an easy way to stretch fuel as far as it can go.

Farm machinery cannot realistically be electrified in the medium-term. But more efficient hydraulic components can still significantly cut emissions. From the perspective of the electrification evangelists, this is less than ideal. But it’s a good deal better than doing nothing!

To continue the conversation about the hydraulics market, get in touch with Brianna today: Brianna.Jackson@InteractAnalysis.com