工业自动化

2021-11-25

为什么工业机器人零部件制造商应以协作机器人为目标?

Tim Dawson

Tim是工业自动化团队的高级研究总监。他拥有20多年的制造业产业研究经验,经常在全球各地的会议和行业贸易展上发表演讲。

Recent years have been tough for the robotics and automation sector. Even pre-pandemic, the situation was challenging. That’s because, in 2019, automotive – a key consumer of industrial robots – saw weakened demand for traditional internal combustion vehicles. Additionally, the electronics market was also stuttering, as was the machine builders’ market. And the expected 2020 rebound was stymied by the COVID-19 crisis, with the global industrial robot market falling by 11.1% in revenue terms, and by 5.9% in shipment terms.

But we are seeing a strong 2021 rebound as end customers resume much-delayed industrial automation projects. Beyond 2021, although activity will not be so frenzied, we predict continued strong growth, not least because the experience of operating factories along social distancing lines has made even the most conservative production line managers think hard about the potential that automation offers. By 2024, the market for industrial and collaborative robots should achieve its previous 2018 revenue peak of $10.5 billion, with 410,000 units shipped.

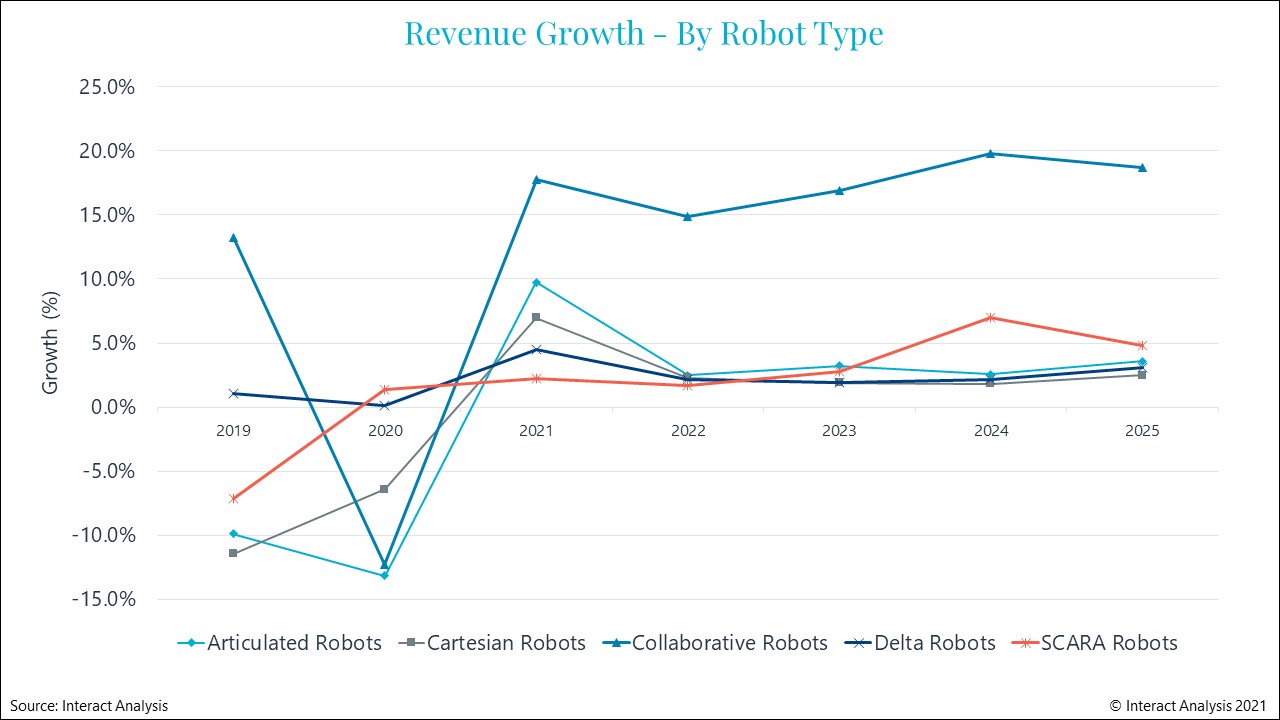

Collaborative robots expected to see 15%-20% annual growth

Before we can understand the robot components sector, we need to look at the changing landscape where industrial and collaborative robots are concerned. In 2020, articulated robots accounted for nearly 75% of the combined $8.6 billion market value of industrial and collaborative robots. But by 2025, we predict that share will drop to 70%, while the combined market will itself exceed $11.1 billion. The reason for this drop is that revenues from automotive, the biggest end-user of articulated robots, will fall from 33.4% of the total market share in 2020 to 31.8% in 2024. Over the same period, the market for collaborative and SCARA robots will see faster than average growth, owing to the emergence of a range of new industries which will constitute strong new markets for these types of robot.

The market for collaborative and SCARA robots will see faster than average

While the overall industrial robot market is forecast to see annual growth of the order of 4% – 5%, the collaborative robot sector is expected to enjoy 15%-20% year-on-year growth. We are seeing a trend towards smaller, lower payload robots, as industries such as electronics continue to automate, and new industries such as battery manufacturing and PV manufacturing increasingly come on stream. SCARA robots with a payload usually of <10 kg, for example, are already the most widely used robot solution in the electronics sector, and have a broad range of applications, including material handling, assembly, and inspection. This clear trend towards smaller robots will heavily impact the robot components sector.

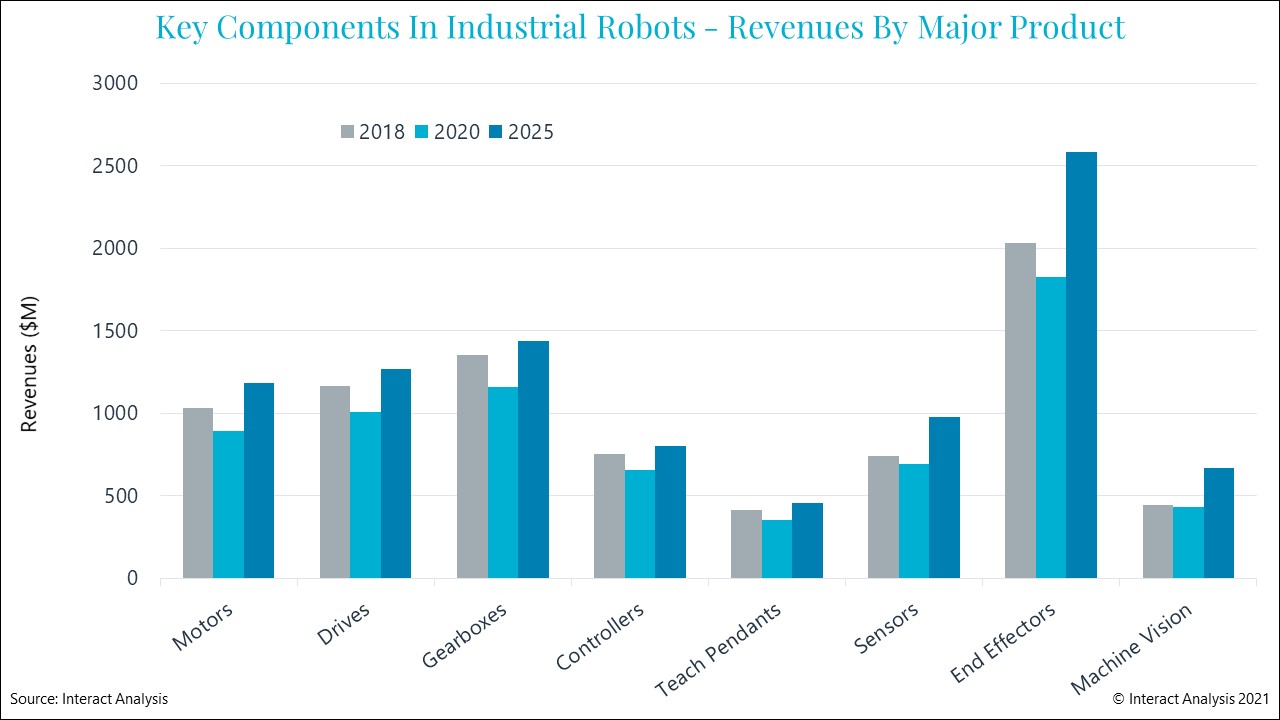

Market for end effectors to top $2.5 billion by 2025

In our latest industrial robot component research, we consider all the key robot components: motors, drives, gearboxes, controllers, machine vision, sensors, and end effectors. 2021 saw a strong double-digit rebound for components used in robots, and this year the market will exceed its 2018 size of just under $8 billion. This is due in no small part to prices being forced up by a number of factors including the semiconductor shortage and inflation. For 2022 and beyond we anticipate lower but still strong levels of growth, with a 4.1% CAGR out to 2025, and revenues projected to hit $9.3 billion that year.

End effectors represent the single largest component market

As we can see on the chart above, end effectors represent the single largest component market, and will continue to do so for the foreseeable future, growing from a market value of $1.8 billion in 2020 to over $2.5 billion in 2025. The combined market for motors, drives and gearboxes is predicted to exceed the value of the end effector market. But there is a significant point to be made here: much of the motors/drives market is captive, with robot manufacturers usually producing these components for themselves. It’s the same story for robot controllers. But markets for other components, including end effectors, teach pendants, sensors and precision gearboxes are far more open to third party suppliers.

Machine vision and end effectors are seeing the highest growth as their penetration is increasing owing to the growing complexity of automation solutions being installed in manufacturing facilities. We are also seeing a slightly above average increase in market share for sensors as the more sophisticated and higher cost absolute encoders see increased use in applications requiring a high degree of accuracy.

The trend towards more compact robots with lighter payloads is creating a demand for smaller and lower power motors, drives and gearboxes which command lower market prices than their larger, more powerful counterparts. So, though these components will continue to dominate in terms of their combined market share, revenue growth will be at a slower pace than for other types of component. Meanwhile, the market for robot controllers is expected to keep pace with the overall industrial robot market, while teach pendants, already well established in the cobot segment, are likely to see slightly increased growth as they are deployed in other robot applications.

Component manufacturers need to target ‘open’ market segments

Whilst the articulated robot sector, by virtue of its size, appears to represent the biggest single opportunity for component vendors, a significant part of the market is captive, with vendors enjoying strong, if not unbreakable, ties with their end customers. Instead, the eyes of component manufacturers hoping to grow their market share should be turning towards the more ‘open’ market opportunities offered by the burgeoning collaborative robot market where revenues are expected to exceed $1.1 billion by 2025, surpassing even the $865 million in revenues derived from SCARA robots.

To talk to Tim personally about market opportunities and trends for industrial robot components, get in touch today: Tim.Dawson@InteractAnalysis.com